There are multiple forms of welding. The most common expressions you will hear someone say are: "I MIG weld" or "I TIG weld", then there is also ARC or stick welding. Instead of just responding with, "that's cool", now you can dive into a deeper conversation about how and what they do!

There are multiple forms of welding. The most common expressions you will hear someone say are: "I MIG weld" or "I TIG weld", then there is also ARC or stick welding. Instead of just responding with, "that's cool", now you can dive into a deeper conversation about how and what they do!

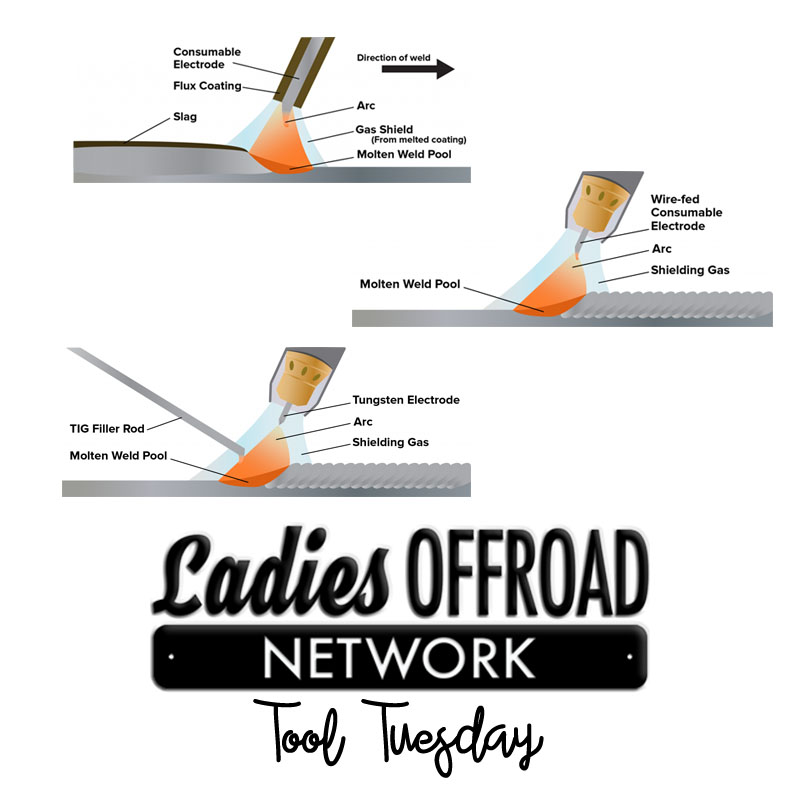

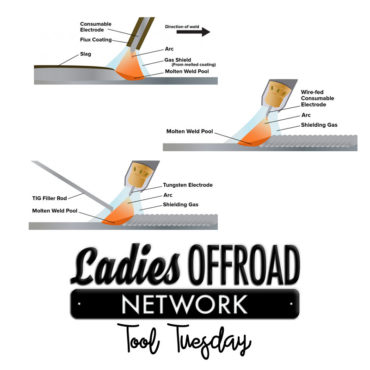

Mig Welding:

MIG welding stands for Metal Inert Gas welding and can also be called GMAW Gas Metal Arc Welding

MIG welding is a "point and shoot" process, sometimes referred as the "hot glue gun" of welding. A MIG welder works by using a continuously feeding spool of welding wire that burns, melts and fuses both the base and parent metals together. The MIG gun, or MIG torch, has a trigger with a nozzle and tip, or electrode. There are different size tips for different size wires that feed through them. The two most complex aspects of MIG are selecting the correct shielding gas and setting the parameters on the machine.

A range of material thicknesses can be welded from thin gauge sheet metal right up to heavier structural plates. You can weld a variety of materials such as mild steel, stainless steel and aluminum, as long as the type of wire and gas are properly chosen. Mig welding is the choice for long distance welding, a foot or more.

There is prep and post work involved with MIG welding It is very important that the weld area is clean before starting. After laying the weld, it is common to use an angle grinder to smooth out welds, although the MIG process can be used to create a high-strength weld with great appearance and little need for sanding or cleaning.

Tig Welding:

TIG welding stands for Tungsten Inert Gas and can also be called GTAW Gas Tungsten Arc Welding

TIG welding is often considered the "major league" of welding. Artists and ornamental welding professionals often prefer this process for its precision and overall clean look. It requires a highly skilled operator using both hands and a foot simultaneously. There is a TIG torch and a pedal that works just like a gas pedal in a car, the harder you push on the pedal, the more electricity goes to the torch, the hotter the arc is, the faster you weld. This two handed process is slow, but when done right it produces the highest quality weld.

What is the word Tungsten? Tungsten is a very hard, slightly radioactive, and brittle metal. Its uses are limited compared to other metals. In TIG welding the tungsten is made into a non consumable electrode that is used to create the arc. Typical other uses for tungsten are in light bulbs, heating elements or any place that requires a very high melting point or the need to pass electricity at a high temperature.

TIG welding is most commonly used for your thinner gauge materials, especially Aluminum. Items made with this process are things like kitchen sinks and tool boxes. The biggest benefits to TIG is the ability to get the power down really low and not heat up and blow through the metal.

The prep work for TIG welding is very important. Both surfaces need to be clean and clear of any debris. Once done, there is no grinding to smooth the weld. TIG is much harder to learn than the other methods, but it is beautiful when done correctly.

ARC or Stick Welding:

ARC or Stick Welding can also be called SMAW Shielded Metal Arc Welding

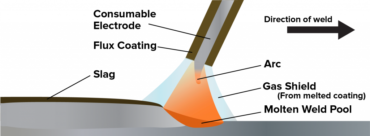

ARC welding is one of the "oldest welding processes" around. It is the rawest form of welding and is great for beginners and hobbyists because it’s easy and affordable. A stick welder uses electricity from the welder that passes through the rod and arcs at the point of contact. The rod begins to melt and the coating around the rod creates a shield from any oxygen that will contaminate the weld. As you move the rod over the joint it keeps melting, more like a spray of metal transferring to the joint, by creating a crater and filling the joint.

ARC welding is fairly versatile being used to weld iron, steel, aluminum, nickel, and copper alloys. It can also be performed outdoors or in windy conditions because it doesn't utilize any gasses.

There are stick welding rods that can burn through rust allowing the rare ability to create an effective bond on rusty or unclean surfaces. However, the finished result of ARC welding isn't very clean. Molten splatter is a common occurrence so a smoothing and polishing grind will be necessary if you are interested in looks, but if you just need a quick weld that isn’t highly visible and doesn’t require a neat bead, stick is a great choice.

The Next Stop

As you can image, there is a lot more to this topic, but at least you know the difference in the definitions. Next, drop by a welding store and check out the different MIG and TIG machines to see what they look like. This will help put the words into perspective!

Author: Charlene Bower

Share with your friends on Facebook: