One of Matt's main complaints when coming home from the shop is "No one ever greases anything!" This is a broad stroke statement as he may have worked on trailer bearings, a dirt bike or a Jeeps front end. There are a lot of maintenance items on your vehicles that by being greased regularly can maintain their life expectancy, otherwise they wear faster and can cause other problems.

One of Matt's main complaints when coming home from the shop is "No one ever greases anything!" This is a broad stroke statement as he may have worked on trailer bearings, a dirt bike or a Jeeps front end. There are a lot of maintenance items on your vehicles that by being greased regularly can maintain their life expectancy, otherwise they wear faster and can cause other problems.

Here are three reasons to grease you may not have thought about: If you love a good power washer as much as I do, you need to be careful when pressure washing into the inner workings of your bearings because you are actually pushing out grease while you are "cleaning". For those that live in wet states with lots of rain, snow or water crossings realize that grease is being washed out continually. Oppositely, if you live in hot climates the grease degrades with the heat, so it's also important to grease more often.

By adding grease you are also pushing out contaminates like dirt and water. $10 for a tube of grease is a lot better than the cost of bearings, seals, steering components, suspension components, driveshaft parts, etc, and the cost of labor to replace them. On the flip-side, you can over-grease, so don't go overboard either. Knowing the signs of over-greasing and under-greasing and how often to reapply can go a long way!

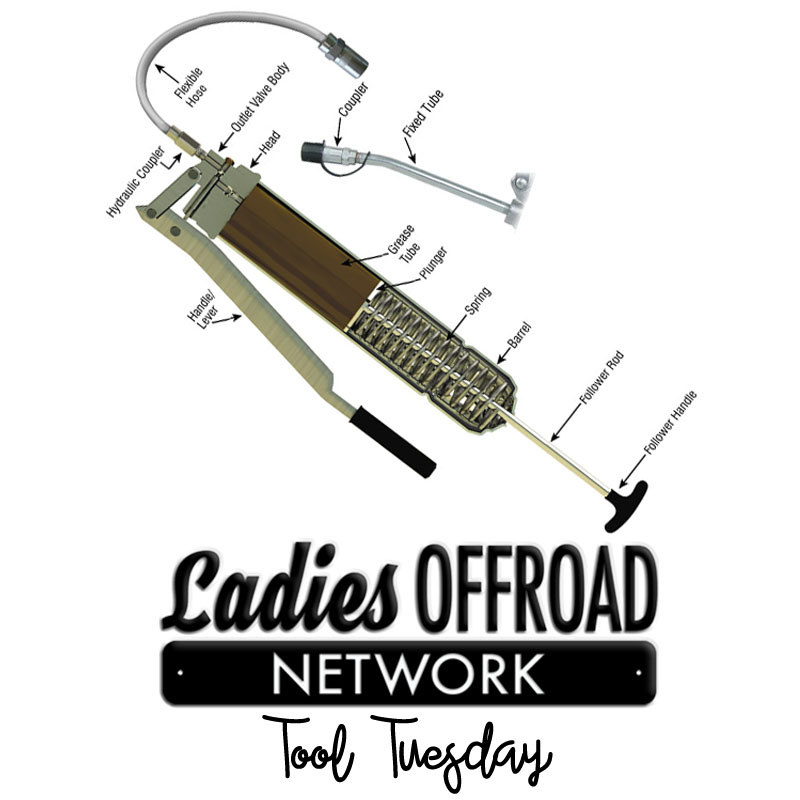

Grease Gun

A grease gun is a great tool to have in your garage, or in your bigger tool box that may travel for longer events. This is not a trail tool that you would need to carry.

There are three ways a grease gun can be powered: by hand, air or electricity. The hand-powered grease guns can either be used with a lever or a pistol grip. The air and electric powered grease guns clearly need an air compressor or power to work. They also tend to be more advanced in applications which isn't necessary for a vehicle. One other major variation to the grease gun is how the grease is loaded: by suction fill, cartridge or bulk.

Coupler

Coupler

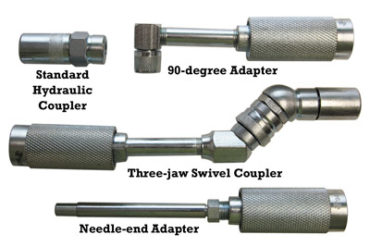

There are many different styles of couplers that are at the end of a grease gun, but there is a standard that is the most commonly used. Other styles include a 90-degree adapter that is needed for fittings in confined areas that require a 90-degree bend, a needle-end adapter that will provide a thin precise amount of grease for tight places, while a three-jaw swivel coupler offers a variety of locking positions for different applications.

Adding A Grease Tube

First you need to disassemble the grease gun unthreading the top piece with the handle and hose from the tube. By pulling the bottom handle back and forward, the old grease cartridge should come out easily. Wipe clean any remaining grease from the  previous cartridge, especially if you are changing the type of grease you are using. Also look for any debris that may have been caught.

previous cartridge, especially if you are changing the type of grease you are using. Also look for any debris that may have been caught.

Pull the handle all the way down and you will be able to feel it lock if you rotate it slightly to the side. Take the rubber cap off the end of the grease (not the metal pull tab). Slide the cartridge into the tube. The metal part will not fit, it needs to be the open end that goes in first. Once the cartridge is in, then you pull the metal tab, like a soda, to open the second end. With the lever still extended, screw the top back onto the tube, but not extremely tight. Take the lever and push any air that may have been collected out the top and then allow the lever to go all the way up into the grease. (Note, it is important to store your grease tubes with the metal tab down so it packs to the right end.) Once the lever is up inside the grease, go ahead and tighten the top onto the tube completely.

If everything is going well and there isn't a lot of air at the top of your grease cartridge, you should only have about 5 or so pumps before grease comes out of the tube and coupler. If you are continually pumping and there isn't any grease coming out, then there is probably an air bubble in the cartridge or line. Go back to the step of slightly loosening the top and then pulling the lever out and locking it to push the air out again. Then repeat the steps to pump the grease out the gun again.

If everything is going well and there isn't a lot of air at the top of your grease cartridge, you should only have about 5 or so pumps before grease comes out of the tube and coupler. If you are continually pumping and there isn't any grease coming out, then there is probably an air bubble in the cartridge or line. Go back to the step of slightly loosening the top and then pulling the lever out and locking it to push the air out again. Then repeat the steps to pump the grease out the gun again.

Zerk Fitting

The Coupler at the end of the grease gun is the female part of the pair, while the Zerk Fitting is a nipple connection that the gun connects to and allows the attached part to be greased. The pressure supplied by the grease gun forces a small ball in the fitting to move back against the force of its retaining spring, essentially a valve opens under pressure to allow the grease to pass and be forced into the voids of the bearing. When the pressure ceases, the ball returns to its closed position to keep out dirt and debris as well as keep in the grease.

Grease Tub

If you are going to pack bearings or want to get down and dirty in the garage, you can buy a tub of grease. Frankly, the few things that an average grease user would need to grease without zerk fittings, you would be fine to use a gun. An example would be adding grease to your trailer ball before putting your trailer on (yes, you don't want it to be dry metal-to-metal).

Grease Types

There isn’t just one “good grease”. There are lots of different types, each one suited for a different application. The most important thing is to identify the best properties for a specific application. There is high temp grease for hubs with disc brakes, grease specifically for the inside of CVs, bearing grease, etc. Grease is a whole other topic!

Whats Next:

Whats Next:

Go look at your vehicle and find all the Zerk Fittings...guaranteed you are going to find quite a few! Now you know what they are and what they are used for! Inquire and understand what the maintenance schedule should be for each part and what type of grease should be used. Then head to the auto parts store (or click below) and get a grease gun and a tube of grease. It's not hard to do the actual physical work. Honestly, it will take a little time to understand what and how much grease to apply where.

Good Option for a Pistol Grip: CLICK HERE

If you have weaker hands, the Lever Grip may work better: CLICK HERE

Author: Charlene Bower

Share with your friends on Facebook: